316L Stainless steel pipe

Classification :

PRODUCT DETAILS

316L stainless steel pipe is commonly used in pulp and paper making equipment, heat exchanger, dyeing equipment, film processing equipment, pipes, materials used for the exterior of buildings in coastal areas, as well as watch chains and case of advanced watches.

|

316L stainless steel pipe |

||||

|

Standard |

Food Grade Sanitary Tube: JIS G3447, KS D 3585, ASTM A270, EN 10357(DIN 11850), AS 1528.1, ISO 2037(NF A49-249) |

|||

|

Heat exchanger tube: ASTM A249 / ASME SA249, GB / T 24593-2009, HG 20537.2 |

||||

|

Industrial pipe: ASTM A312, EN 10217-7, GB / T 12771-2008, HG 20537.3 |

||||

|

Drinking water tube: GB / T 19228 |

||||

|

Mechanical tube: ASTM A554, EN 10296-2 |

||||

|

Size |

Outer Diameter Range: 9.5~2000mm |

|||

|

Shape Section |

Round, square, rectangular |

|||

|

Usage |

Sanitary tubing: for food processing industry, beverage industry, sugar mill and so on; |

|||

Features:

1.Our stainless steel tubes pipes are treated by bright annealing, inside weld bead removing, precise polishing. The roughness of tubes could be under 0.3μm.

2.We have the non destructive testing ( NDT ), eg. online eddy current inspection and hydraulic or airtightness testing.

3. Thick welding, good appearance.The mechanical properties of tube could be tested.

4. The raw material is from Taigang, Baogang, Zhangpu and so on.

5. And Our tubes are certificated by AD 2000-W0, PED 2014/68/EU, ISO 9001 : 2015.

6. Full material traceability is guaranteed during the manufacturing process.

7. Polished tube is supplied in individual plastic sleeves with capped ends ensuring optimum cleanliness.

8. Internal Bore: Tubes have a smooth, clean and crevice free bore.

Warehouse Storage

The company currently has more than 300 employees and 22 domestically advanced hot-dip aluminum-zinc silicon steel plate production lines. The annual output is 900,000 tons; it has 3 to 3 color coating production lines with an annual production capacity of 240,000 tons, and one printing production line with an annual production capacity of 11,000 tons.

Packing and shipping

Business areas include: galvanized coils, color-coated coils, carbon steel, stainless steel, aluminum mesh coils, printed coils, embossed coils, color steel tiles, etc.

Technology

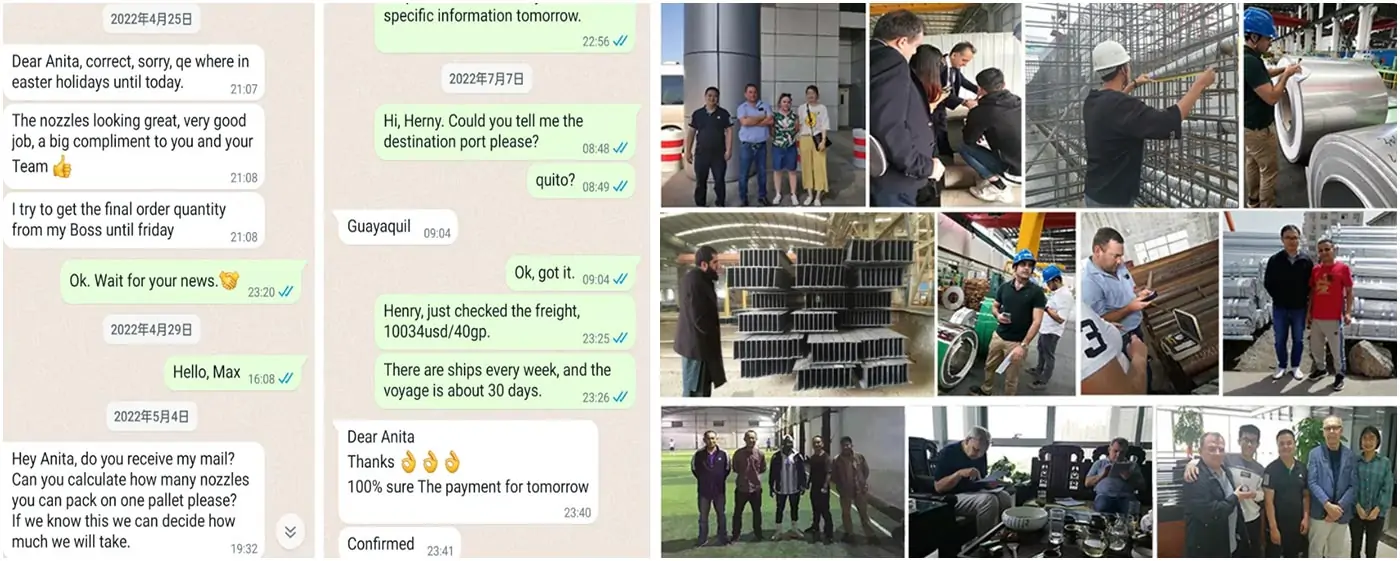

Customer communications

The business has developed rapidly, and a broad network has been established in China to provide professional and high-quality services to domestic customers. By further integrating sales channels.

Application field

The company's products can be widely used in aircraft manufacturing, petrochemical industry, shipbuilding, construction pipeline transportation and other industries.

FACTORY WORKSHOP

Our products are well sold in China and exported to many countries, such as South Korea, Japan, Russia, Germany, Britain, Austria, Czech Republic, Hungary, Netherlands, Slovenia, Bulgaria, Egypt, Saudi Arabia, Iran, Kuwait, UAE, Turkey, Israel, Syria, Lebanon, Jordan, Yemen, Cyprus, Philippines, Vietnam, and Malaysia...

Customer Visit

Customer Visit

Production Workshop

Factory Workshop

Production Workshop

FAQ

How about the delivery time?

What are the shipping ports?

Can you give warranty of your products?

How long does your delivery time take?

Does the product have quality inspection before loading?

RELATED PRODUCTS

GET A FREE QUOTE