Preparation method of carbon steel pipe

The raw material of carbon steel pipe is round tube blank, which needs to be cut and processed by a cutting machine to form a billet with a length of about 1 meter, and then sent to the furnace for heating through a conveyor belt. The billet is fed into the furnace for heating, with a temperature of approximately 1200 degrees Celsius.

16

2022

/

09

Discount SPCC Carbon Steel Plate: The Best Choice for Your Steel Needs

Steel is an essential material commonly used in various industries due to its durability, strength, and versatility. One of the most commonly used types of steel is carbon steel, which is known for its cost-effectiveness and excellent mechanical properties. Among the several types of carbon steel, Discount SPCC Carbon steel plate has gained popularity among industries because of its excellent properties and cost-effectiveness.

08

2022

/

09

In what fields can stainless steel coils be used?

The application of stainless steel in the automotive industry should be regarded as a relatively developed application field of stainless steel plates. Using high-strength stainless steel plates as the manufacturing raw materials for the vehicle body structure can greatly reduce the weight of the vehicle and enhance the strength of the overall vehicle structure. If the vehicle panels are made of stainless steel plates, maintenance costs can be effectively saved.

16

2022

/

09

How are stainless steel pipes classified?

Stainless steel pipes are divided into ordinary carbon steel pipes, high-quality carbon structural steel pipes, alloy structural pipes, alloy steel pipes, bearing steel pipes, stainless steel pipes, as well as bimetallic composite pipes, coated and coated pipes to save precious metals and meet special requirements. There are various types and uses of stainless steel pipes, with varying technical requirements and production methods. The current production of steel pipes has an outer diameter range of 0.1-450mm and a wall thickness range of 0.01-250mm. To distinguish its characteristics, steel pipes are usually classified according to the following method.

06

2023

/

03

Four processes of steel bar processing

The processing of steel bars generally involves four processes: rust removal of steel bars; Straightening of steel bars; Steel bar cutting; Forming of steel bars. When the steel bar joint is connected with straight or conical threads, it is also necessary to add the steel bar end upsetting and thread processing procedures. Rebar batching and replacement Rebar replacement

02

2022

/

01

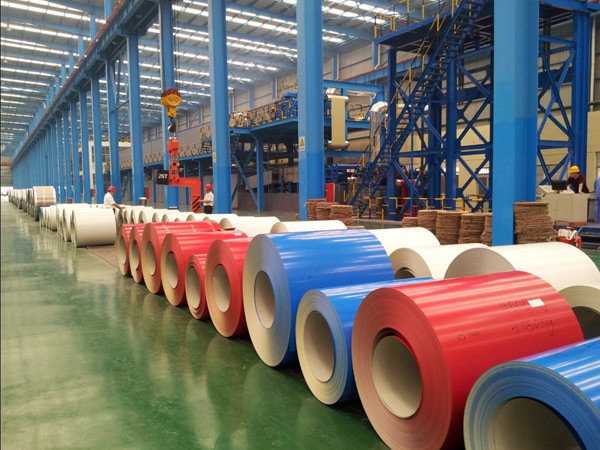

What are the inspection standards for color coated rolls

Inspect the appearance of the color coated roll, including the smoothness, color, and absence of obvious scratches, dents, bubbles, foreign objects, etc. on the coating surface. The appearance requirements should meet the product specifications and relevant national standards.

16

2022

/

09